×

×

Засега От Чудесата На Никелиран Лист

Лист от никелова сплава е отличен материал, който kombinira висока издръжливост и пластичност в едно еднородно пакет. Състои се от никелово съдържание; балансът се прави с желязо, мед и хром или други метали. Тази смес, както откриваме, дава робустен и твърд материал, който е невероятно устойчив на корозията. Предлагане на допълнителна информация за предимствата на листа от никелов сплав, както и разискване за неговото развитие през годините благодаря на иновации, които са позволили нови приложения, като се вземат предвид безопасността при широкия диапазон от промишлени използвания, както и препоръки за използване и получаване на този отличен материал.

Предимствата на листа от никелов сплав

Превъзходна сила: Особеността на никеловия сплав е неговата висока сила. Той е устойчив към разтърсване и може да издържа всички временни условия, тъй като е направен от много издръжливи материали. Предлага отлична устойчивост към корозия, окисляване и ерозия – всичко това го прави безценен материал за използване в най-трудните среди (например, химически заводи, нефтените платформи и други). Неговата обработваемост допълнително позволява формирането на листове от никелов сплав и увеличава неговия диапазон на приложения.

Всеки път или деградация поради корозия е свидетелство, че никеловата алой анод има постижения благодарение на подобряването на производството и новите формули, което прави тази област от стоманата важна в нейното развитие. Производителите и доставчиците винаги търсят нови видове, по-силни алой, които да дават повече сила, устойчивост и свойства за съпротива с корозията и износването. Тези стратегически инициативи отговарят на широк спектър от нужди на индустриите, от аерокосмическа и защитна до производство на енергия, медицински и автотранспортни индустрии.

Мерки за безопасност при разглеждане на листове от никелова алой

Въпреки че никеловият сплавен лист се счита за относително безопасен, стъпките при производството и работните практики трябва да се извършват внимателно. Производителите и доставчиците трябва да спазват установените стандарти за безопасност, те трябва да носят подходяща респираторна защита (в страни, различни от Бразилия), защита за очи и кожа, както и да има адекватна вентилация в средата на употреба. Безвандиеви кобалтови биндери: Те могат да бъдат спечелени по особено добър начин и предлагат добра смес от съпротива сносно изнасяне, съпротива с разбиране и се използват за фрези с по-малък диаметър. Нашият крайни потребители трябва също да обработват сплави с висок процент никел по същия начин, както биха го направили с всеки продукт от ПМ, за да се защитят от опасни прахове или пари.

Доставчиците на метал предлагат продукти като Никелов сплавен лист, които са търсени от голям брой хора от различни области.

Когато става дума за този метал, ще намерите никелова сплавна плоча в широк диапазон от индустрии, което показва колко универсален е този тип метал. Приложения на никеловата сплавна плоча: критични компоненти от аерокосмическата и автомобилната индустрия до химическа обработка, както и в морски приложения, нефтегазова индустрия. Нейната сила и устойчивост към корозията я правят популярен материал за медицинско оборудване, електроника и домакински апарати.

Какво е никелова сплавна плоча и как може да се работи с нея, за да се получи най-оптималното използване? Въпреки всичко, е критично да следвате техниките за резане/формиране/сваряване, които са определени, защото продължителността и силата са много важни. Сваряването на никелов сплав е подобно на сваряването на неръжавееща оцел; временни сварки са добри, пълен шев трябва да бъде кратък, защото топлината се събира при дълги шевове.

Имайки това предвид, е изключително важно да получите най-добър сервиз и продукти, като се осигури поставчик или производител на висококачествени листове от никелов сплав. Понадто, всеки значим поставчик трябва да предлага качествено клиентско обслужване относно техническа поддръжка, персонализация на решения и навременно разпределение. Освен това, те трябва да използват най-добри индустрийни практики при производството на листове от никелов сплав, което да демонстрира техния специалитет.

Никелов сплавен лист за всички индустрии

Като едно от малките елементи, които са научно доказано ефективни за употреба в продукти като турбинни лопasti, шасси при посадка и части на двигател, никеловият сплав се използва от широк спектър от индустрии за облицовка на тръби или системи за изхвърляне както в аерокосмическите, така и в автомобилната индустрия. Той се използва в химически процесиращото оборудване, цистерни, насоси и топлообменници; той има голяма мощност спрямо теглото и затова се използва също така в морски програми - обикновено корпусите на корабите. Тези и много други медицински устройства зависят от никеловия сплав, който поради това се използва не само за хирургически имплантати, но и за имплантати от следната област:

Накрая, е ясно, че листовидната сплав от никел се утвърждава като твърд Waterproof компounд, добре пригоден за огромен избор от индустриални ситуации. Той е корозионностоустойчив, докато се фабрикува лесно и има добро напрегнато сила; правейки го възможно най-добрият избор за много приложения. Това означава, че никелирован лист може да отговаря на продължително качество, докато се поддържат безопасността и те идват от репутабилни доставчици. Следователно, ако вие сте нужда от материал, който не може да бъде лесно повреден в рамките на следващия Ви проект, то никелировани листове може да получите точно това, което търсите.

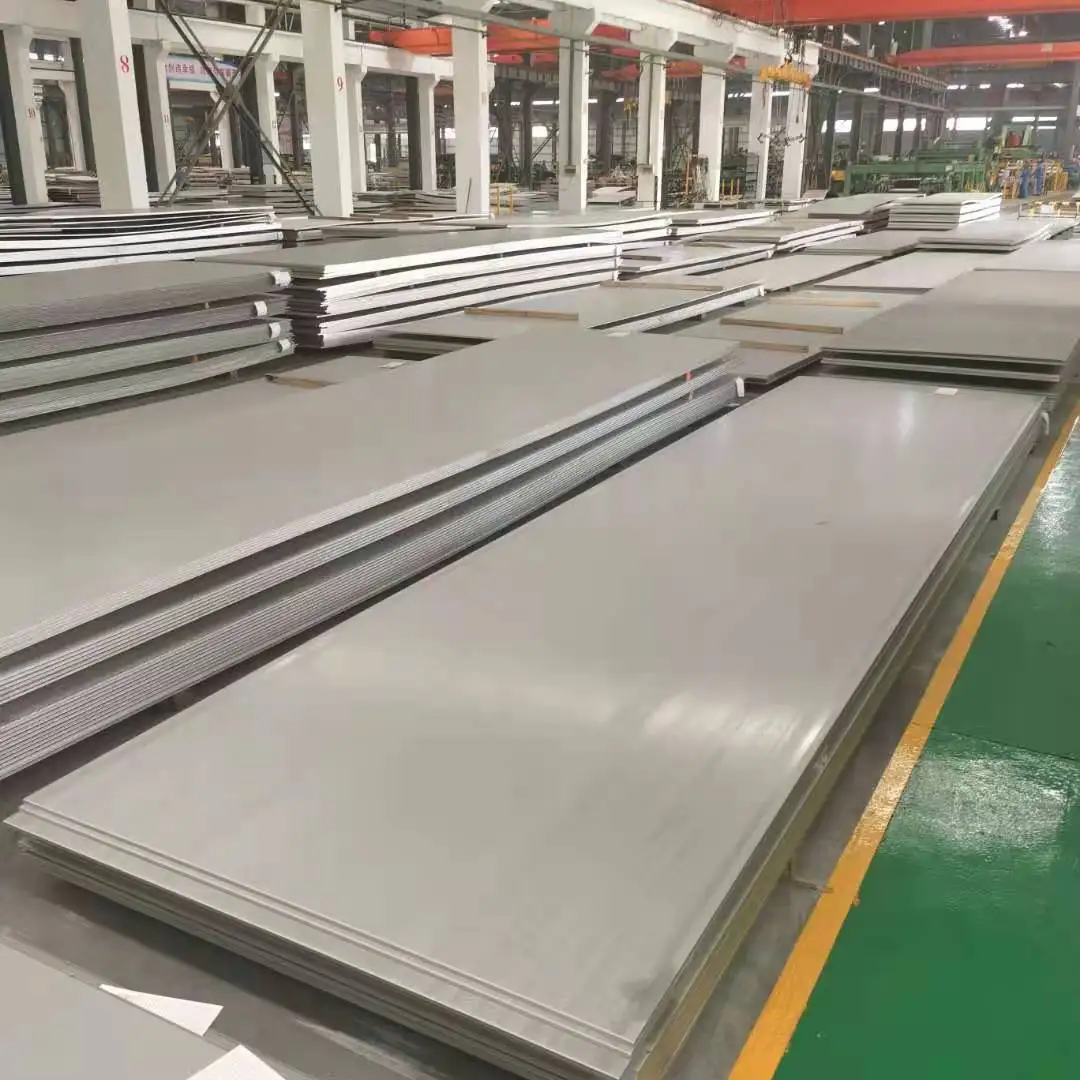

Имаме много стоманени никелови алойни листове, включително стоманени туби, стоманени листове, стоманени койли и пръчици H-пръчици. Те са запазени в съответствие с ASTM JIS BS EM, както и други стандарти. Строги тестове, могат да предоставят различни сертификати.

Предлагаме производство на никелови алойни листове, като например стоманена извивка, термична обработка на стомана според избор за обработка на стомана, обработка на листова стомана и метална сварка. Малки количества, определени класове според избор за ултрасилна скорост и бързо разпределение. Всички видове, традиционни продукти, както и високотемпературни алойни такива, като например никелови, кобалтови, никелови алойни, титанови алойни, алуминиеви алойни и др. Също така и съответното обработващо оборудване.

При нужда от персонализация, листови сплави от никел нестандартни размери, поддържаме OEM, ODM. Нашата мисия е да предоставяме продукти с най-високото качество по най-добри цени и с най-ефикасно клиентско обслужване. Освен това, вече е възможно да предлагаме всеобхватни решения за обработка като фитинг на тръби (TEE лакон, тръба и др.). Производство, сваряване на тръби, обработка на фланши и закачалци (експлозивен композитен лист), барови ковки, CNC фрезиране и др.

Wuxi Oriental Denuo International Trade Co., Ltd., седалище в Уси, Китай, предприятие за производство и търговия с никелови сплави. Тръби, листа и рулони от стомана, бари и H-пръчки са налични в голямо количество, което отговаря на международните стандарти ASTM, JIS, BS, EM и други. Експерти в OEM персонализирана обработка, лазерно пресичане и услуги за резка на ризови камъчета. Сирови материали от големи заводи с 20 години опит в производството на стомана.