×

×

An Interest In The Wonders Of A Nickel Alloy Sheet

Nickel alloy sheet is an excellent material, combining both high tensile strengths and ductility into a single uniform package. It consists of a nickel content; the balance is made with iron, copper and chromium or other metals. This mixture as we discover makes for a robust and tough material whilst also being incredibly corrosion resistant. Offering additional depth regarding the benefits of nickel alloy sheet, as well as discussing its development over the years thanks to innovation that have enabled new applications while paying heed for safety precautions right through a broad range industry uses together with recommendations on using & sourcing this most excellent material.

The benefits of Nickel Alloy Sheet

Outstanding Strength: The speciality that nickel alloy sheet offers is its high strength. It is crush-proof and able to withstand all weather conditions, as it made of very durable materials. It offers excellent resistance to corrosion, oxidation and erosion - all of which make it an invaluable material for use in the toughest environments (e.g., chemical plants, oil rigs among others) Its workability additionally makes nickel alloy sheet shaping possible and increases its application range.

Every time or degrades due to corrosion is a testament that nickel alloy sheet anode Nickel-based superalloys have advanced with better manufacturing and new formulations, which makes the field of such steel imperative in its evolution Manufacturers along with Suppliers always seek for new grades, stronger alloys which will give more strength, toughness and corrosion & wear resistant properties. These strategic initiatives address a wide range of industry needs, from aerospace and defense to power generation to medical as well automotive industries.

Safety Measurements while Considering on Nickel Alloy Sheet

While a nickle alloy sheet is considered to be relatively safe the production working steps have to performed and practices had observed cautiously. Manufacturers and suppliers must comply with established safety standards, they should wear appropriate respiratory protection (in countries other than Brazil), eye and skin protection as well as have adequate ventilation in the environment of use. Vanadium-Free Cobalt Binders: They can be sintered particularly well and offer a good mix of wear resistance, break resistance are used for End-mills with smaller diametersOur end users must also handle higher nickel alloys in the same manner as they would any PM product to protect themselves dangerous dusts or fumes.

Metal suppliers offer products like Nickel Alloy Sheet in demand by a large number of people from different walks.

Where this metal is concerned, you will find nickel alloy sheet in a wide range of industries and that reflects just how versatile the type of metal it actually is. Applications of Nickel Alloy Sheet: critical components from aerospace and automotive sectors to chemical processing, as well as in marine applications, oil & gas industry Its strength and corrosion-resistance qualities also make it popular material for medical equipment, electronics and home appliances.

What is nickel alloy sheet and how can it be worked with to deliver the most optimal use? Either way its critical to stick with the how-to cut/form/weld techniques your boys upstairs have laid out because longevity and strength is hot key. Welding nickel alloy is similar to welding stainless steel; tack welds are fine, full beads should be kept short as heat builds up from long seams.

With that in mind, it is very important to get the best service and products by securing top-of-the-line nickel alloy sheet supplier or manufacturer. Moreover, every significant supplier ought to supply quality customer care regarding tech aid, solution customization as well as on-time distribution. Additionally, they need to make the most of sector quality nickel alloy sheet that demonstrate their specific niche as well.

Nickel Alloy Sheet For All The Industries

As one of the few elements that are scientifically proven effective for use in products such as turbine blades, landing gear and engine parts, nickel alloy sheet is used by a wide range of industries lining tubes or exhaust systems in both aerospace sectors and automotive. It is utilised in chemical processing gear, tanks, pumps and warmth exchangers; it likes large power to weight percentage and so for the exact function as marine programs - hulls of vessels normally. These and many other medical devices rely on nickel alloy sheet, which is therefore used to make not just surgical implant but also implants from the following field:

At the end of the day, it is clear in hindsight that nickel alloy sheet catches on as a tough waterproof compound well suitable for an enormous selection of industrial situations. It is corrosion resistant while being easily fabricated and having good tensile strength; making it a top choice for many applications. This means that nickel allow sheet can meet a lasting quality, as long as safety guidelines are maintained and they come from reputable suppliers. Therefore, if you are in need of highly dependable material that cannot be damaged easily within your next project then Nickel alloy sheets can possibly get exactly what you seek.

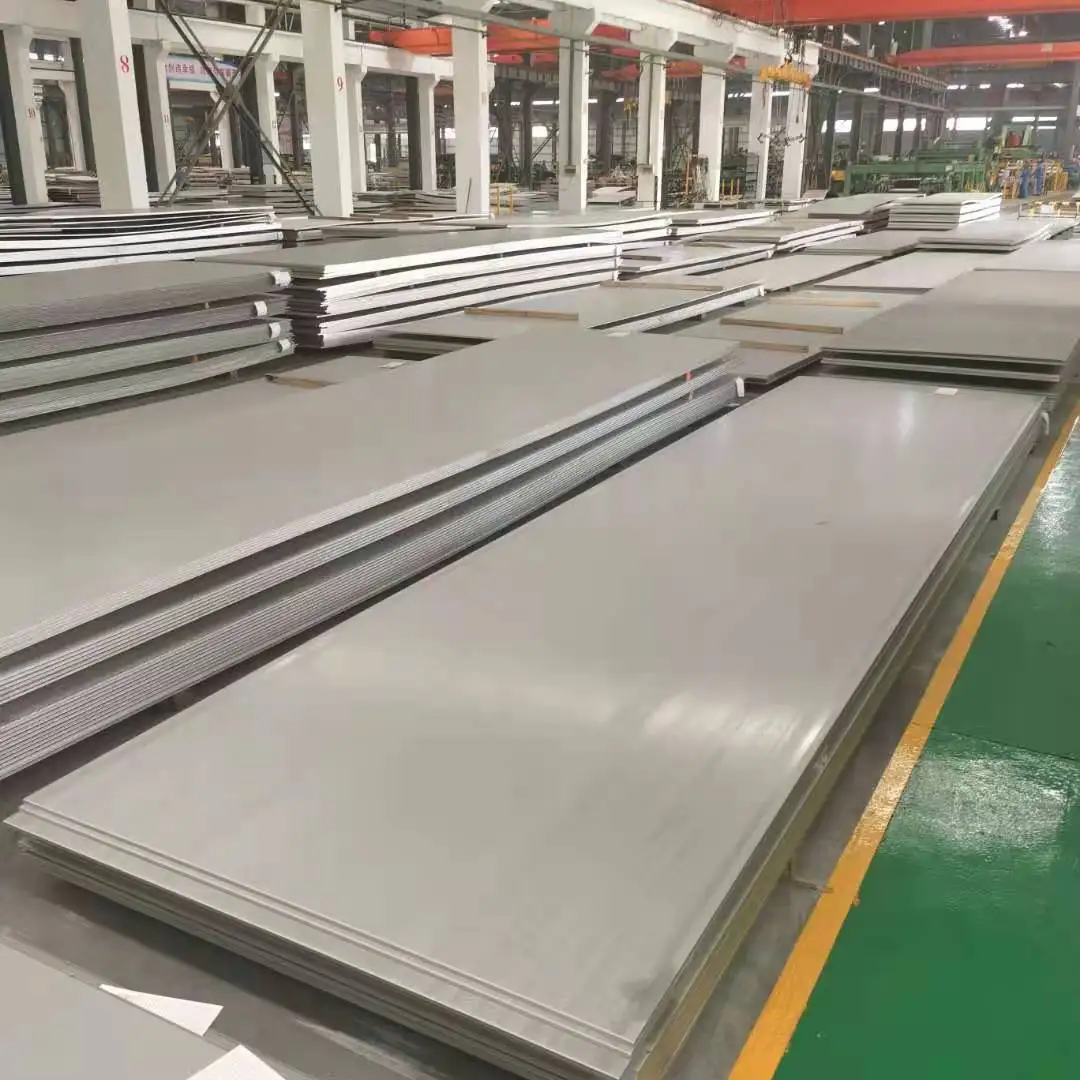

We have many steel nickel alloy sheet, including steel tubes, steel sheets, steel coils and bars H beams. They have been stocked in compliance with ASTM JIS BS EM aswell as other standards. Strict testing, can provide varied certificates.

We provide manufacturing nickel alloy sheet, such as steel bending, steel heat-treatment in choice to steel processing, sheet steel processing, and metal welding. Smaller amounts, certain grades in choice to speed that is ultra-high and distribution that is fast. All-type, traditional products along with a high heat alloys such in terms of instance nickel-based, cobalt-based, nickel-based alloys, titanium alloys aluminum alloys., etc. Also, the related processing equipment.

On need customization, nickel alloy sheet non-standard size, support OEM, ODM. Our mission to provide highest-quality products at the best costs and the most efficient customer service. In addition, have made it possible provide one-stop processing solutions like pipe fitting (tee elbow, pipe, etc.) Production welding pipe processing processing of flange fasteners (explosive composite plate) Bar forging, CNC milling, etc.

Wuxi Oriental Denuo International Trade Co., Ltd., located in Wuxi, China, a nickel alloy sheetenterprise integrating production trading. Steel pipes, steel sheets steel coils bars, H beams, etc. are all available in huge quantities. available, that are in compliance with ASTM, JIS, BS, EM and other international standards. Experts in OEM custom processing, laser cutting rhinestone cut services. Raw materials from major factories fine processing 20 years' experience in the production of steel.