×

×

One great material is low carbon steel plate which provides fantastic strength and versatility across a range of applications. Low carbon steel refers to a very low percentage of carbon content that tends towards the range of 0. Not expressing verse shapeability is participating in best wiring and duct work, as these traits raise gears straight into Windows programs rather than values remaining at zero tools are torn away(bitxerewries seen bond weakened).

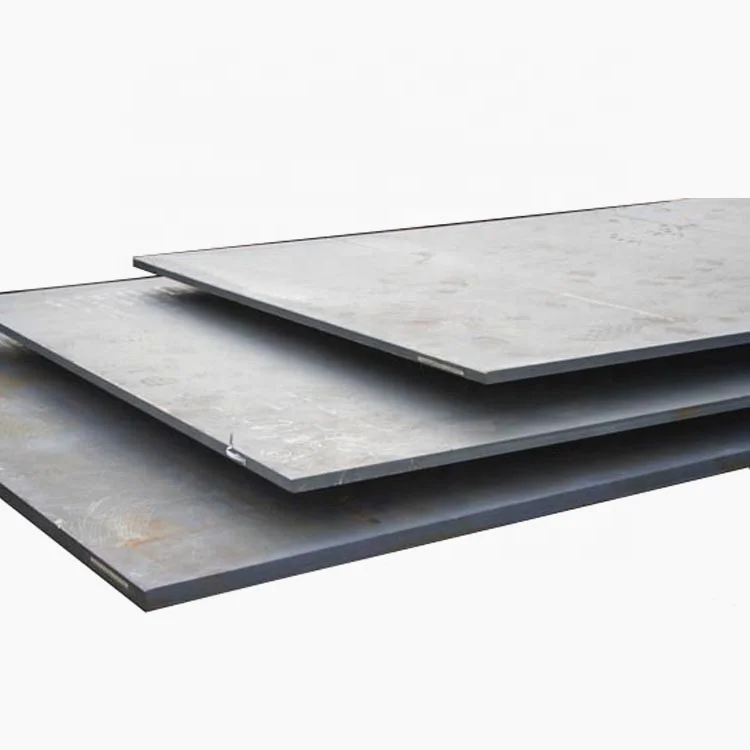

There are many benefits of low carbon steel plate in manufacturing applications.It shows the material have good features. It is compatible with the strength requirements that steelmakers are seeking and can be used in many things from cars to planes. It resists breaking, cracking and it can withstand bending/shaping processes which make the material a valuable asset in manufacturing industries.

Post: The merits of using Low Carbon Steel Plate in an Industrialist Field

Multiple Benefits of Using a Low Carbon Steel Plate From the perspective of a manufacturer, it can be quite advantageous to employ low carbon steel plate. Not only is it greener in the sense of a low carbon footprint and better energy efficiency during production, but also has improved workability. This is because of it's ability to be very stiff but also pliable enough that the object forged from this material will bend, and form into the mold while having only a bit part-sufficient brittleness.

Regrettably, not all know about being involved in this line as well as just how versatile the low carbon steel plate is and its wonderful application throughout countless industries. This steel have applications as varied as wear- resistant forging dies, all the way to large highrise casings or bridges. These properties also make it applicable in a wide range of applications from kitchenware to home appliances showing how simple and versatile this metal is.

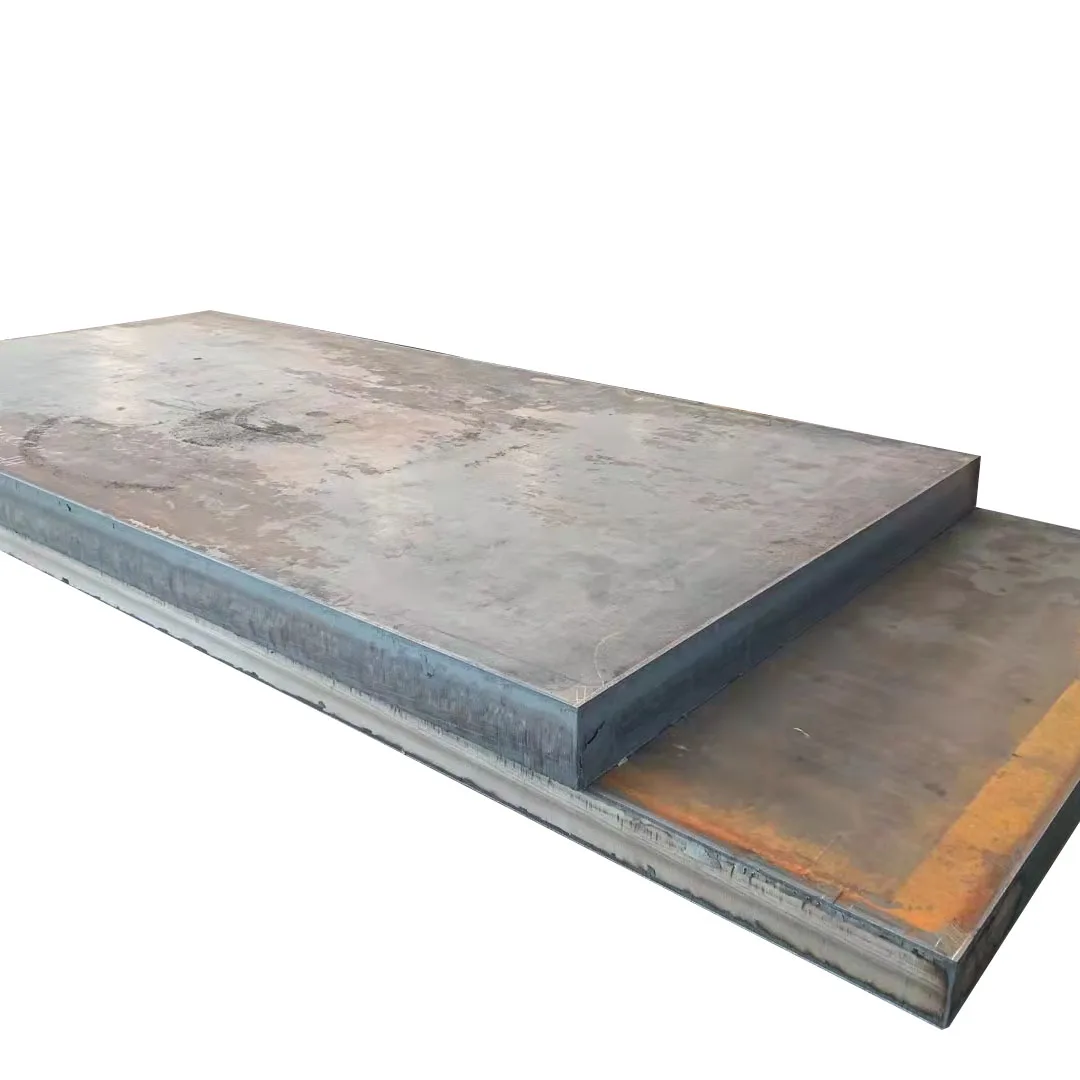

Its value and flexibility make it indispensable in the production of an enormous range and variety of items all around many industries. It allows for the production of components like car frames and engine parts, among others within automotive. It is also used in the reinforcement of beams and girders for construction. At the same time, broadly defined this is an important part of manufacturing as such in making other machine details (eg tracks), machines and devices required for industrial processes.

It is now new that a low carbon steel plate will play an important role in manufacturing as the world becomes more awareness of sustainability and environmental conservation which are expected to be sustainable. Its low-energy assembly process and small environmental impact make it a great solution for any company hoping to lower their carbon signature. This coupled with its ease of use means it could also be the most adaptable alloy-metal on this list, from which all kinds bars for cutting to tools or even complex high-performance materials such as aircraft.

In Conclusion, The low carbon steel plate is a versatile material for manufacturer that have good quality and it also can save the environment. Reducing the carbon in production of CNF should lead to a material which is stiff, durable and easy workable -- yet can be easily processed by equipment that manufacturers have already bought. In this case it will find applications across industries because we are currently without any materials with mechanical properties fitting between anything available on mass produced market today. Given the societal focus upon sustainability, it seems probable that low carbon steel plate will become a significant growth area both inside and outside of manufacturing.

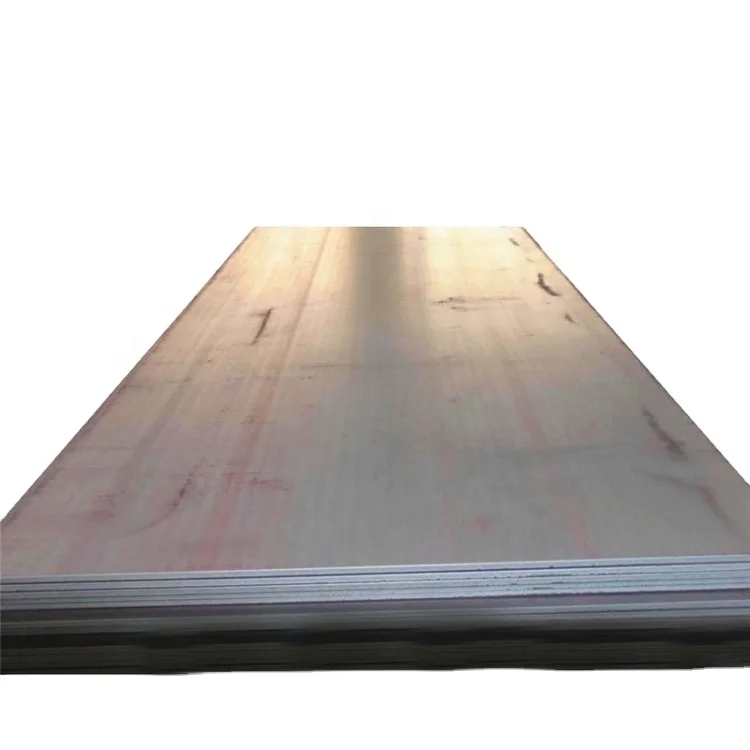

Wuxi Oriental Denuo International Trade Co., Ltd. A large-scale low carbon steel platelocated Wuxi, China, integrates manufacturing and trading. Steel pipes, steel sheets, steel bars coils, H beams, etc. are all available in huge quantities. available, and in accordance with ASTM, JIS, BS, EM other international standards. Experts in OEM custom processing, laser cutting and rhinestone cut services. Raw materials factories, major factory Fine processing, 20 years experience in the field of professional in the production of steel.

On need customization, acceptable non-standard size, support OEM, ODM. It is our aim provide you with the highest-quality products the most affordable price, the best service. In addition, we have also developed one-stop low carbon steel plate supporting services, such pipe fitting (tee elbow, pipe, etc.) production, welded pipe processing, Flange fastener process explosive composite plate forging bars, CNC machining, etc.

we offer manufacturing low carbon steel plate, such as metal bending in addition to metal heat treatment metal processing solutions, sheet and welding steel processing. Special specifications, special grades, small batches, ultra-high-speed distribution, fast delivery times. We offer both conventional and products which are complete. We also offer high-temperature items like cobalt based and alloys which are nickel-based.

A range is carried by broad us of items like low carbon steel plate, steel sheets, steel bars and coils H beams, for instance. offered, in compliance with ASTM, JIS, BS, EM along with other international standards. Strict examinations, provides certificates.