×

×

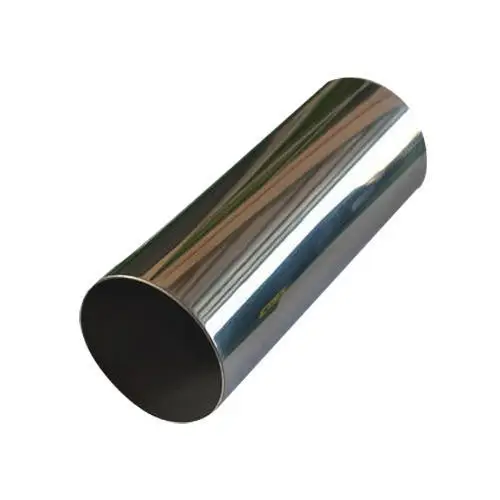

As the term metal evokes then 316 stainless steel tube act perfectly in this respect and when we talk about metal tubes working within factories etc, conducting job like heating, cooling. For this reason, that particular metal alloy is used in so many application We then discuss some of the beautiful characterstics in further detail.

Now, for the purpose of this post we will look at what makes it so well received and also why you ought to would like a part from your 316 stainless-steel pipes into two different classes then provide certain levels under individuals. This is true especially for the material having corrosion resistance properties, making it a perfect option in severe environment applications. It is most well known for its durability, very low maintenance and has a modern style. Its wide variety of uses is a good showcase for the applicability of it, including but not limited to which:

Food and Beverage Industry- Acid resistant so this can be used for the process of liquids & gases or even in storage tanks because it's corrosion resistance to acidic substances.

Chemical industry: This material is used in chemical production, which will be subjected to high temperatures and ground conditions.

MedTech: everything that belongs to surgical instruments and implants as well for all other devices used in the medical industryFactories.

Common Employ: Build regarding fishing boats; track for that hulls and also installing.

Having discussed the purpose and advantages of 316 stainless steel tube, lets focus on its particular attributes. It is a better alloy due to its higher strength and ductility along with improved resistance against corrosion -- at least 16% chromium, 10 % nickel andalong with the addition of molybdenum (around2%). 316stainless steel tube characteristics:

This forms an excellent transi-tion to the recommendations by Thomas et al that, evenasaustenitic stainless steels are usually used in similar environments, fabricators should not forget pitting / crevice corrosion behaviour especially where high levels of Chromium (Cr) or Molybdenum may lead aggressive Martensitic grades SAgrades.

Tensile Strength and Elongation - High Tensile (however Ductility because of the flex) where applications require pressurization greater than 7 TORR or some form thereof.

Unbreakable: It is highly resistant to heat and does not change the shape even at high temperature condition which suits any application that needs exposure to higher temperatures like furnaces, or use in a variety of applications such as with aluminum dross.

EASY TO CLEAN AND MAINTAIN - with the smooth surface,it is more easier to clean and maintain.

BENEFITSHigher corrosion resistance compared to 304Showcases the excellence of stainless metal two.Replaces other sorts of components in many capabilities

We touched on this in the use of non-standard terms for a bit, so i will need to explain just why 316 stainless steel seems almost impervious to corrosion. Rust refers to the oxidation of metal as a result of contact between it and air, water or others highly reactive chemicals. It also contains a varying percentage of Chromium and nickel, the more that is in there - generally speaking unless you get to some high end exotic Stainless steels - the better its going ot be with regards to corrosion (which again compared to other alternatives for stainless steel tubing should deal well). Then why 316 stainless steel tubesOutperforms other types of Stainless Steel?

Because of its high chromium content: 316 stainless steel pipe has excellent corrosion resistance to many corrosive agents, such as all kinds of acid, alkali and salt compounds by forming a hyperchromic oxide passivation layer.

There is an increase in molybdenum, which increases: Molybdenium impairs resistance by chlorides and aggressive chemical influences.

Low carbon content in the 316 Stainless Steel Tube, rendering it resistant to carbide precipitation induced intergranular corrosion than most other stainless steel categories.

How to Select the Appropriate 316 Stainless Steel Tube for Your Industrial Applications

Now that you have learned (or refreshed) your knowledge of 316 stainless steel tube utility, features and roles - the next question arises: which shape to choose based on an industry need. One type is figuring out which affiliate programme you would like to choose and for this, there are certain elements that you have to keep in mind and we will discuss about 3 of them.

Sizing And Geometry: It is also important to get the diameter of tube that suits your application a selection off tubes with difference sizes and geometry's should be available for you.

Temperature and Pressure Compatibility: Discovering the area of temperature or pressure under which any application will operate, it is important to work what tube can meet these without losing its functionality.

Environmental friendly- more molybdenum tubing is products for the bad chemistry and saltwater, to decrease rust.

Cost Evaluation: Size and thickness of the tube are identified as well to determine costing effects, which helps in reaching a budgeted decision.

And to conclude the tete-a-tete on 316 stainless steel tube here is an instance that stands as example for its flawless utilization in real life. Somehow both products brought me back to the 316 stainless steel tube used by BASF (a world leader in chemicals) for its chemical processing infrastructure. This is because of its high corrosion resistance and heavy pressure applications. In turn this choice has significantly heightened the high-level service reliability and safety associated with their operations, as well causing a major decline in ownership costs through savings in maintenance.

So in conclusion the best of all with massive corrosion-resistance whether strength flexibility, and heat tolerance are joined together wrapping up to 316 stainless steel tube. These applications make it suitable for various industrial uses, such as chemical processing and food & beverage treatment to marine operations and medical environments. In the selection of tube type you have to take in account size and shape, temperature and pressure limit as well exposure into aggressive environments. It is important to consider budgeting factors as well Strength and Durability are both excellent with 316 Stainless Steel Tube, it wears the champ crown for being versatile tube in a competitive economic price meeting majority of industrial tubing requirements.

Wuxi Oriental Denuo International Trade Co., Ltd., located in Wuxi, China, a 316 stainless steel tubeenterprise integrating production trading. Steel pipes, steel sheets steel coils bars, H beams, etc. are all available in huge quantities. available, that are in compliance with ASTM, JIS, BS, EM and other international standards. Experts in OEM custom processing, laser cutting rhinestone cut services. Raw materials from major factories fine processing 20 years' experience in the production of steel.

We have many steel 316 stainless steel tube, including steel tubes, steel sheets, steel coils and bars H beams. They have been stocked in compliance with ASTM JIS BS EM aswell as other standards. Strict testing, can provide varied certificates.

We offering manufacturing 316 stainless steel tube like metal bending, heat-treatment of steel and metal processing. We also offer sheet metal processing, and steel welding. Lower quantities, specific grades rate that is high and shorter distribution times. Standard products, complete kind, furthermore offer temperature alloys that is nickel-based, cobalt built alloys, titanium alloys aluminum alloys, etc. These are only an examples which may feel few. And processing which is comparable.

On need customization, acceptable non-standard size, 316 stainless steel tube OEM, ODM. is our aim to offer the highest quality products at best cost and most reliable service. Additionally, we've also created one-stop processing solutions like pipe fitting (tee elbow, tie, etc.) Production pipe, welding, Flange-fastener processing (explosive composite plate), bar forging, CNC milling, and more.